Ergonomic Considerations for Assembly Line Workers

Ergonomics plays a critical role in optimizing the performance and well-being of assembly line workers. By understanding the principles of biomechanics, employers can design work environments that reduce the risk of injury and promote efficiency. Assembly lines often involve repetitive tasks that can lead to musculoskeletal disorders if not addressed properly. Ergonomic assessments help identify potential hazards and recommend modifications in workstation design. For example, adjustable workstations can accommodate different body types and preferences, allowing workers to maintain proper posture. Furthermore, retraining employees on proper lifting techniques and task variation can significantly minimize strain. The addition of supportive tools, such as ergonomic chairs, anti-fatigue mats, and specialized tools, can further enhance comfort and productivity. Additionally, integrating regular break schedules can help mitigate fatigue and maintain focus on tasks. Organizations can also consider implementing team-building activities that promote communication and collaboration, fostering a supportive work culture. Overall, addressing ergonomics in assembly lines leads to improved employee satisfaction, reduced absenteeism, and enhanced quality in production. Organizations should prioritize ergonomics as a core value to ensure the health and productivity of their workforce.

Key Components of Ergonomics in the Workplace

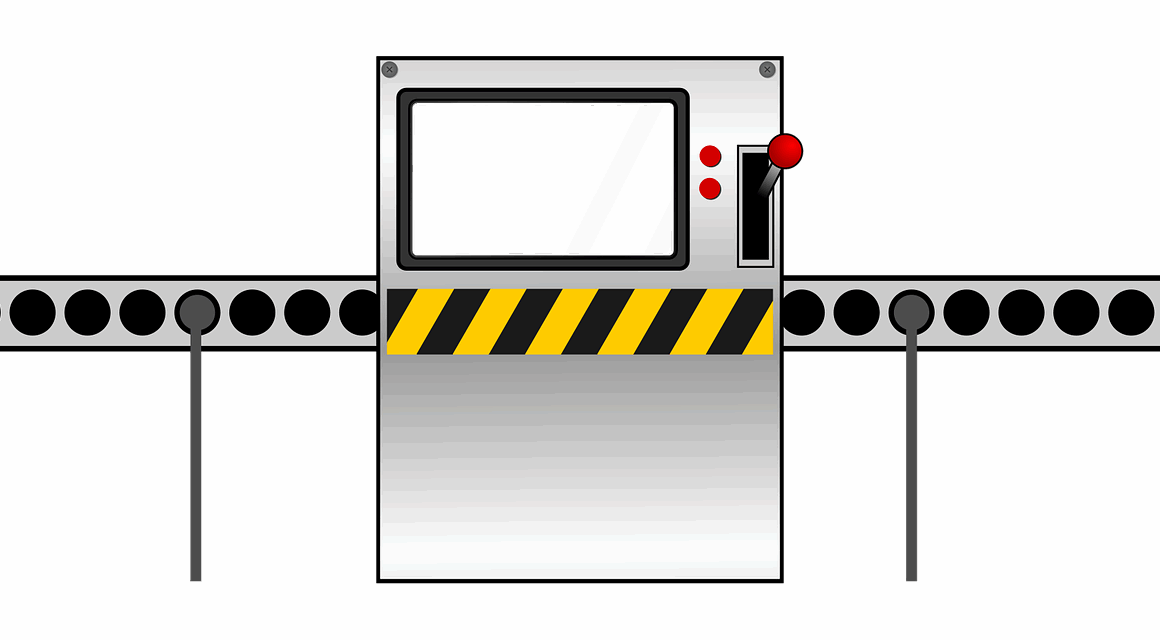

To achieve optimal ergonomics in assembly line settings, several key components must be considered. One essential factor is workstation design, which should allow ample space and flexibility for various tasks. This may include adjustable heights for work surfaces and the placement of tools within easy reach to minimize extended reaches or awkward postures. Another important element is the evaluation of tasks performed on the assembly line. Workers should be rotated through different roles to prevent repetitive strain injuries. Additionally, incorporating equipment such as conveyors can reduce manual lifting and carrying, which are primary causes of work-related injuries. Training is critical in promoting ergonomic practices; employees must be educated on how to adjust their workstations and employ proper body mechanics. Understanding the signs of strain and fatigue is equally important so that they can address any issues promptly. Companies should regularly conduct ergonomic assessments and solicit feedback from workers to ensure continued improvements. By fostering an ergonomic workplace culture, organizations can significantly enhance employee safety, engagement, and overall productivity. Implementing these components involves a proactive approach to creating healthier work environments for assembly line workers.

The role of management in promoting ergonomic practices cannot be overstated. Leadership must commit to implementing changes that enhance worker safety and comfort. They should advocate for proper funding and resources allocated toward ergonomic assessments, training, and workplace modifications. Organizing workshops that educate employees on the importance of ergonomics can be a valuable investment. Industry leaders must also collaborate with ergonomic specialists to develop tailored solutions that address specific needs within their assembly lines. Regularly revisiting ergonomics allows organizations to adapt to new technologies or changes in production processes. Performance metrics related to employee health and productivity should be tracked and analyzed to measure the effectiveness of ergonomic interventions. Furthermore, communicating the benefits of ergonomic improvements to employees reinforces their importance and encourages buy-in from the workforce. This promotes accountability as workers feel empowered to adopt ergonomic practices. Establishing a reporting system for injury incidents tied to ergonomics can also facilitate ongoing improvements. Overall, having management support and involvement is crucial for fostering a culture of ergonomics within the workplace.

The Importance of Training in Ergonomics

Training in ergonomics is essential for assembly line workers to ensure their safety and well-being. Comprehensive ergonomics training programs educate employees about proper lifting techniques, posture, and the importance of taking breaks to alleviate fatigue. Exercises that promote flexibility and strength can also be integrated into these programs, helping workers build resilience against common injuries. Role-playing scenarios can give workers practical experience in applying ergonomics knowledge to their daily tasks. Additionally, refresher courses should be scheduled regularly to reinforce ergonomic principles and address any evolving challenges. Workers should feel empowered to seek out ergonomic adjustments without fear of backlash from management. Training should also foster a culture of communication, where workers can freely discuss ergonomic concerns and suggestions. Maintaining open channels of dialogue between employees and management encourages innovation and can lead to better ergonomic practices. Companies that prioritize training in ergonomics experience lower injury rates and increased employee morale. Employees who are knowledgeable about ergonomics are more likely to follow best practices, contributing to a safer and more efficient work environment. Investing in ongoing ergonomics training yields substantial returns in terms of productivity and worker satisfaction.

Engaging workers in the decision-making process regarding ergonomic solutions is another effective approach in assembly line environments. Conducting surveys or focus groups enables employees to express their experiences and suggest areas for improvement. Their firsthand knowledge about specific tasks provides valuable insights that management might overlook. Highlighting success stories from employees who have benefited from ergonomic changes can help illustrate the advantages of addressing these issues. Recognition programs can also amplify workers’ contributions by incentivizing suggestions for ergonomic interventions. By fostering teamwork, organizations can empower employees to collaborate on ergonomic initiatives, ensuring that any modifications meet their needs. Regularly scheduled feedback sessions can create opportunities for ongoing discussions about ergonomics. The inclusion of workers’ input into ergonomic designs leads to higher acceptance and adherence rates. Also, emphasizing the connection between ergonomics and overall health can garner increased interest from the workforce. Strategies to promote ergonomics, such as placing posters and signage around the workplace, will further instill the importance of these practices. Ultimately, involving employees in ergonomics creates a more engaged, aware, and productive workforce.

Potential Challenges and Solutions

Despite the numerous benefits of implementing ergonomic strategies, challenges may arise that hamper these efforts. Resistance to change from employees or management can pose barriers. To overcome this, it is vital to engage stakeholders from the outset and seek their input on proposed changes. Change champions within the organization can advocate for ergonomic initiatives, encouraging others to adopt new practices. Financial constraints may also limit the implementation of ergonomic solutions. To address this, companies can prioritize interventions based on the level of risk associated with specific tasks. Simple adjustments, such as repositioning tools or altering workflows, often require little investment yet yield significant improvements. It is also essential to establish a clear and realistic timeline for implementing ergonomic changes, allowing for phased introductions. Further, continuous monitoring and evaluation of ergonomic interventions help identify areas in need of adjustment, ensuring that efforts remain effective. When creating ergonomically friendly environments, remember to gather data on employee satisfaction and productivity metrics. This information will be vital in justifying future investments in ergonomics. By proactively addressing potential challenges, organizations can create an enduring culture of health and safety.

In summary, prioritizing ergonomics for assembly line workers is crucial for maintaining their health, safety, and productivity. By considering workstation design, educating employees, and involving them in ergonomic interventions, organizations can create a supportive workplace. Management commitment is vital in facilitating these changes and ensuring continual monitoring and improvement. Companies should acknowledge the value of ergonomics not just as a regulatory requirement but as an integral part of their operational strategy. Investing in ergonomic programs leads to substantial benefits, including reduced injury rates, lower absenteeism, improved morale, and enhanced overall productivity. Building a culture centered around ergonomics will forge stronger teams and healthier work environments. When workers thrive, productivity naturally follows. This holistic approach to ergonomics will ensure a sustainable and successful assembly line operation, with employees feeling valued and responsible for their safety. Organizations must strive for excellence in all aspects of their operations, and ergonomics should be a priority. As companies adapt and evolve, the ongoing evaluation of ergonomic practices remains crucial. The future of assembly lines will be increasingly reliant on these principles, influencing worker engagement and organizational success.